IS YOUR FACILITY OR PLANT IN COMPLIANCE WITH NFPA 70E? Does your plant have an updated and accurate one-line diagram which is essential to worker and operational safety? Is your electrical equipment correctly rated and able to withstand available fault current? IF you answered yes to any one of these items, your facility and, more importantly, your employees could be at risk. NFPA compliance takes more than a label and personal protective equipment. It must integrate correctly into a properly defined safety program.

DINTER ENGINEERING can perform ARC-flash hazard studies using EasyPower software to analyze the electrical power system. The equipment data for system modeling and documentation can be collected using your employees, an electrical contractor or Dinter employees to work within your budget and timeframe.

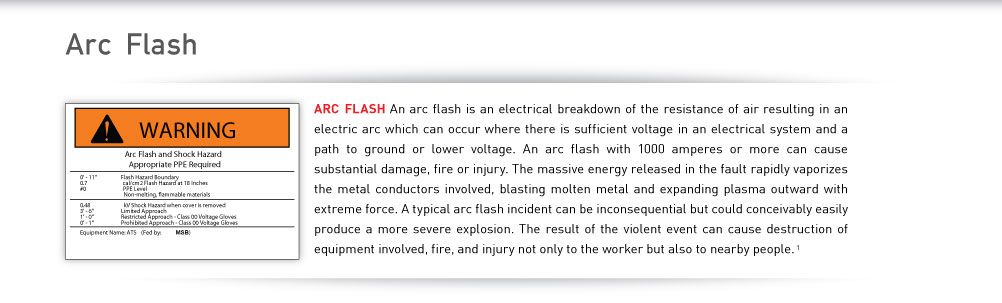

Once the data is collected, a system model can be created and fault and coordination studies performed. Arcing currents as determined by these studies can then be applied to determine arc hazard incident energies, arc-flash boundaries, working distances and PPE requirements. This information will be transferred to the arc-flash label and affixed to the appropriate electrical equipment. Don’t put off compliance with NFPA 70E and OSHA requirements any longer; promoting electrical safety makes good sense!

Arc Flash. (n.d.). Retrieved May 20, 2011 from 1 http://en.wikipedia.org/wiki/Arc_flash